Powerdrive self-drilling screws (for metal roofing/cladding) consist of three series, each series with a different corrosion resistance class for optimized corrosion protection depending on applied environment.

All series have many fastener lengths with several head-styles and drill-points.

Series available – JR Series, JC3 Series, JC4 Series, and STX Series.

Overview

| Series | Corrosion Resistance | Coating | Steel |

|---|---|---|---|

Light industrial/Urban environment

Category 2 per ISO 9223 |

Ruspert grey or silver | Carbon steel | |

Moderate industrial environment

Category 3 per ISO 9223 |

Zinc-Tin | Carbon steel | |

Severe industrial environment

Category 4 per ISO 9223 |

Zinc-Tin | Carbon steel | |

| Ruspert silver | Bi-metal: Carbon steel & Stainless Steel-304 |

*Mechanical data such as pull-out loads, tensile & shear strength of each series can be found in the brochure downloads.

Specifications

| Specifications | ||

|---|---|---|

| Steel | : Grade 1022 carbon steel | |

| Coating | : RUSPERT grey or silver | |

| Corrosion Resistance |

: ASTM B117, 1000-hours accelerated salt spray test | |

| Application | : External use with moderate levels of condensation | |

| Head Styles | ||

Hex

|

Pan

|

|

Wafer

|

Flat

|

|

| Drill Points | ||

|

DX for fixing to steel | |

|

SD for fixing to thick steel | |

|

RX for fixing to thin steel or timber | |

|

TD for fixing to timber | |

| Specifications | ||

|---|---|---|

| Steel | : Grade 1022 carbon steel | |

| Coating | : Zinc-tin (80/20) @ 25-µm thick | |

| Corrosion Resistance |

: AS 3566.2 Class-3 | |

| Application | : External use in mild, moderate industrial/marine environment | |

| Head Styles | ||

Hex

|

Pan

|

|

Wafer

|

Flat

|

|

| Drill Points | ||

|

DX for fixing to steel | |

|

SD for fixing to thick steel | |

|

RX for fixing to thin steel or timber | |

|

TD for fixing to timber | |

| Specifications | ||

|---|---|---|

| Steel | : Grade 1022 carbon steel | |

| Coating | : Zinc-tin (80/20) @ 45-µm thick | |

| Corrosion Resistance |

: AS 3566.2 Class-4 | |

| Application | : External use in moderate, severe industrial/marine environment | |

| Head Styles | ||

Hex

|

||

| Drill Points | ||

|

DX for fixing to steel | |

|

RX for fixing to thin steel or timber | |

|

TD for fixing to timber | |

|

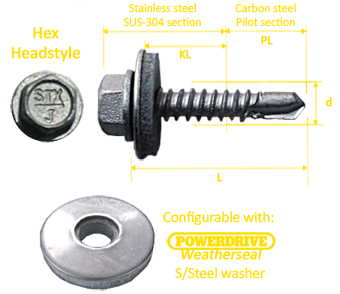

BIMET principlePowerdrive STX® screw series’ head & loadbearing shank is made of non-hardened SUS-304 stainless-steel (18/8) containing 18% Chromium and 8% Nickel, while the drill-point (pilot) section is comprised of hardened steel. This bi-metal principle effectively combines stainless-steel rustfree performance with excellent drilling & threadforming capabilities of the hardened steel pilot section. STX®is a registered trademark of Powerdrive (PJ) Sdn Bhd. Characteristics

|

STX® selection of sizes

| Part No. | Screw dia |

Shank length |

Clamp-up length |

Pilot section |

|---|---|---|---|---|

| # | d mm | L mm | KL mm | PL mm |

| STRX.520HM.S16 | 4.8 | 19 | 9 | 10 |

| STDX.525HM.S16 | 4.8 | 25 | 12 | 13 |

| STDX.662HM.S16 | 5.5 | 62 | 48 | 14 |

| STDX.675HM.S16 | 5.5 | 75 | 61 | 14 |

| STSD.638HM.S16 | 5.5 | 38 | 13 | 25 |

|